The essential difference between military SSD and consumer SSD is their security and reliability, not the speed performance.

And What cause their security and reliability such a big difference? The answer is design idea and material selection!

The cost of SSDs differs from several times and even more, though using the same capacity and the same chipset, when adopting different design idea and material.

The design idea of consumer level SSD is performance prior and cost saving, for instance, when can use 4 layers, they won’t choose 6 layers, moreover, if some material can be omitted then they will leave out. While military SSD will put reliability in the first place, if 10 layers needed then 10 layers, and all the materials is military or industrial standard. Because of these different thinking, it makes big difference between consumer and military level SSD.

1. Working/Operation Temperature

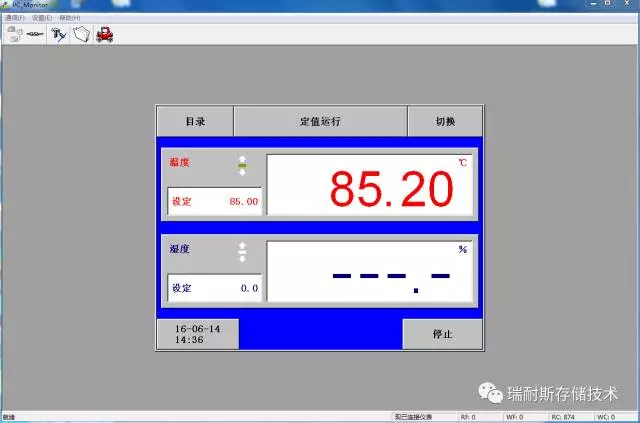

Usually -40°C to +85°C, even -55°C to +125°C temperature range of military SSD is common requested, while consumer level SSD just request 0°C to 70°C working temperature range.

Under the low or high temperature environment, electric performance changes greatly, military SSD products have high standard on material selection, not only all electronic components must be industrial standard, but also require high requirements on PCB cabling and circuit board. As known, ordinary PCB will blister after highbake (e.g. 260°C) for more than 2 times, circuit board layers will be broken, which leads into poor connection. While the PCB of military SSD will not has such problem even under the same condition. How to judge the quality of PCB? The simple way is putting the PCB into a 260°C roaster undergoing and repeatedly baking for several times, until the PCB surface becomes pasted if no blister, then qualified.

2. Reinforcement Process

2.1 Glue

Firstly, the chipset of military SSD will be reinforced by glue, then will be solidified under 160°C heat. The glue not only connects the PCB with chipset, but also completely discharges the air of chipset pin, preventing the chipset pin from oxidating in the future, what’s more, waterproof.

(How to do? Rencie will use German brand glue and make each chipset glued through the robotsealing, tilted 45 °C for 30 minutes to let the glue automatically infiltrate until the air emptying, and then heating, the whole gluing process takes more than 1 hour.)

2.2 Rugged Connector

Usually ordinary SATA connector is planar contact structure, whose structure is simple manufacture and low cost, but if applied in lots of vibrations and jerks environment, such planar contact structure will have transient poor connection condition, then leads into signal disappear or data loss, therefore, military SSD will use special customized rugged SATA connector.

Internal structure of R-SATA connector:

This kind of rugged connector won’t have poor connection condition regardless of any direction of vibration and shock. Of course, using rugged housing is another way of military SSD reinforcement.

3. Push-to-trigger Destruction Function

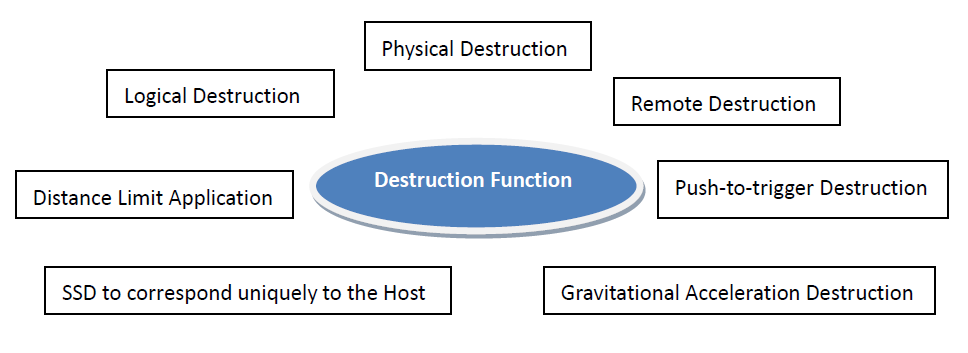

Consumer level SSD doesn’t have requirement on some special functions, but military SSD does, data destruction is necessary in some conditions:

Physical destruction design is not just simply added some circuit, actually it’s hard to burn because the flash itself carries with circuit-protection feature, meanwhile, different Nand flash increase the difficulty of burning. Renice have done lots of test experiments and find out a way to ensure all the flash will be burned out.

http://www.renice-tech.com/html/2016/04/27/201604270301491655582064.html

4. Reliability

So we can see from the reliability of military SSD and find out that it needs to take a wide range of factors into consideration, and requires a lot of testing, debugging and verifying. While consumer grade SSD doesn’t need to go through these process.

(Reliable SSD manufacturer: http://www.renice-tech.com Email: may@renice-tech.com)