In ITS (Intelligent Transportation Systems), PIS (Passenger Information System) and other embedded in-vehicle application, such as video surveillance, data recorder…usually or sometimes the voltage changes unstably, SSD as embedded memory and storage device when doing data video recording is aggressively affected by the unstable input voltage.

First of all, please let me introduce RBER (Raw-Bit Error Rate), RBER is the Bit Error Rate before ECC (Error Correction Code) performing, reflects the initial reliability of Nand flash. The higher RBER, the less reliability of Nand flash.

Then, how Input Voltage Affects the Nand Flash of SSD?

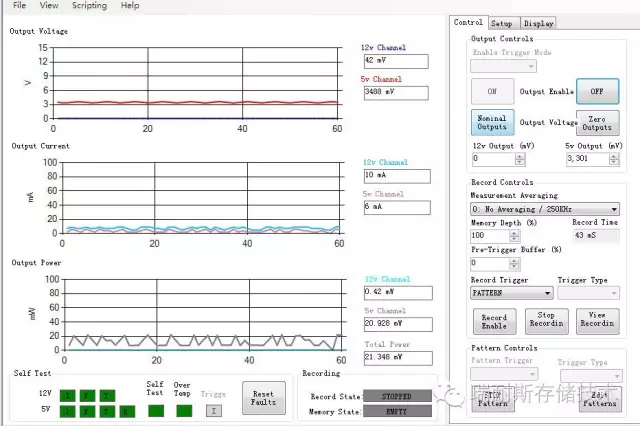

Firstly, per 0.3V as a voltage difference in set time, the below graph is 3.3V-3.6V fluctuation.

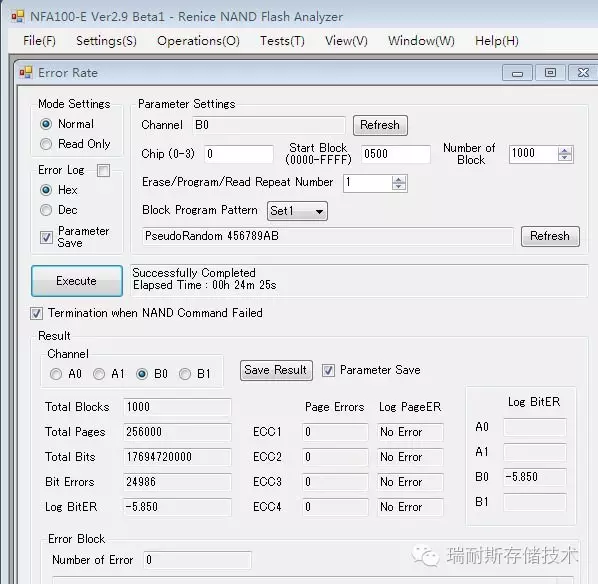

(1) When setting 2.7V – 3.V (standard voltage range of NAND flash), the RBER of NAND flash is 10^(-5.850), which is in normal range.

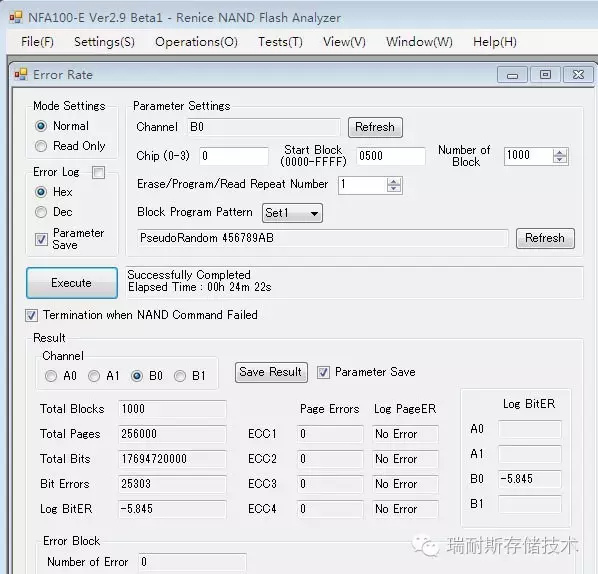

(2) When setting as 3.6V – 3.9V, the RBER begins to increase, reach at 10^(-5.845).

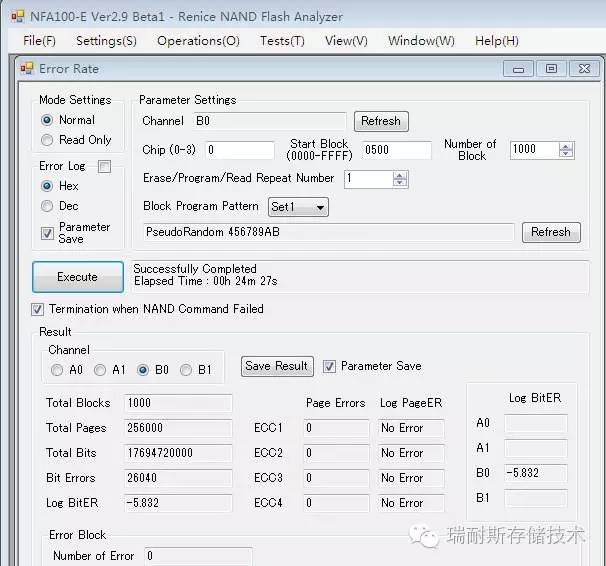

(3) When Voltage range is 3.9V – 4.2V, the RBER is 10^(-5.832).

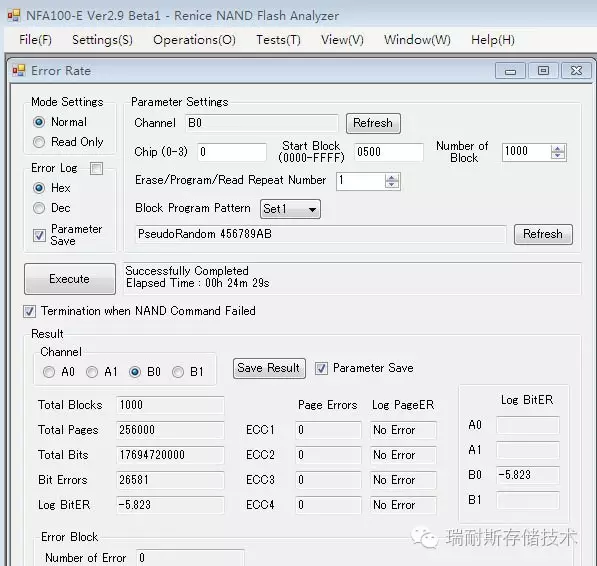

(4) When setting as 4.2V – 4.5V, the RBER keeps growing and up to 10^(-5.823).

Generally, the higher input voltage, the higher RBER, the greater impact to SSD performance.

Renice engineers will design the appropriate circuit according to SSD’s acceptable varying voltage, which will make sure our SSD can show high and stable reliability performance in harsh/extreme environment.

Besides, Renice SSDs design with Power Failure Protection (Power Fail Management), Over voltage and inrush current Protection, qualifiedly pass Extended/Wide Temperature Tolerance test (-50°C ~ +90°C), Anti-Vibration test (16.4G(10-2000HZ), Anti-shock test 1,500G(@0.5ms half sine wave).

(Note: all the test result based on Renice Nand Flash Analyzer: http://www.renice-tech.com/html/2015/12/29/201512290249452690962089.html)

Consult: may@renice-tech.com